INDICATED HORSE POWER – The actual power developed within a cylinder as calculated from the indicator diagram.

INDICATED WORK – The work of compression plus the work of expulsion of the air from the cylinder minus the work done on the piston by the pressure of the air during admission.

INLET LINE LOADER – An unloader that automatically opens and closes the inlet line under pressure variations in the receivers.

INTERCOOLER – A type of surface heat exchanger placed between two cylinders of a two stage compressor so that heat of compression generated in the first stage cylinder may be removed (in part or whole) from the air as it passes through the intercooler to the second stage cylinder.

ISOTHERMAL COMPRESSION – Compression of air at constant temperature. Law of compression is PV= constant.

IMPENDING SKID – The tyre traction point at which any increase in side or tractive load will produce tyre skid.

INDEPENDENT SUSPENSION – A type of suspension system in which each wheel is independently supported by a spring. A suspension that allows up and down movement of one wheel without affecting the opposite wheel.

INNER TUBE (tyre) – The inside rubber tube assembled in the tyre casing, it maintains the air at sufficient pressure to inflate the casing and adequately support the vehicle weight.

INTEGRAL BODY – has the longitudinal and cross members of the chassis incorporated in the frame work of the load carrying body. With this arrangement, part of the load previously carried by the chassis, is diffused through the body structure.

ISOFLARE – A brake tube flaring method that upsets the tube and allows a strong, secure attachment when used with the proper tube nut and seal.

IGNITION LAG – The time interval between the start of injection and start of ignition. Also called DELAY PERIOD.

INDIRECT INJECTION ENGINES – have the combustion space divided into two parts connected by a nozzle or one or more number of orifices. The fuel is injected into the auxiliary chamber. The main chamber is situated in the piston top.

INJECTION LAG – Time interval between the closure of the fuel pump ports by the plunger and the begining of fuel injection by the injector.

INJECTION PUMP – A high variable pressure pump delivering fuel into the combustion chamber.

INJECTION SYSTEM – The components necessary for delivering fuel to the combustion chamber in correct quantity, at the correct time and in a condition satisfactory for efficient combustion.

INJECTION TIMING – Crank angle with respect to TDC at which fuel injection starts, during the compression stroke.

INJECTOR – A device for injecting fuel oil into the combustion chamber of an engine against the pressure of air within the chamber. Also called INJECTION NOZZLE.

IMPRESSION – Cavity in a die casting die or in a mould.

INCLUSIONS – Particles of slag, sand or other impurities such as oxides, sulphides, silicates etc., trapped mechanically during solidification or formed by subsequent reaction of the solid metal.

IN GATE – Channel out from the bottom of the runner into the mould. It is used in cases where the runner does not enter the mould direct.

INJECTION – Forcing molten metal into a die casting die.

INOCULATION – Process of adding some material to molten metal in the ladle for the purpose of controlling the structure to an extent not possible by control of chemical analysis and other normal variables.

INSULATING SLEEVE – Hollow cylinders or sleeves formed of gypsum, diatomaceous earth, pearlite, vermiculite etc., placed in the mould at sprue and riser locations to decrease heat loss and rate of solidification of the metal contained in them.

INTERNAL CHILLS – Solid pieces of metal or alloy, similar in composition to the casting, placed in the mould prior to filling it with molten metal.

INVESTMENT MOULDING – Moulding using a pattern of wax, plastic or other material which is invested or surrounded by a moulding medium in slurry or liquid form. After the moulding medium has solidified, the pattern is removed by heating the mould, leaving a cavity for reception of molten metal. Also called LOST WAX PROCESS or PRECISSION MOULDING.

IMPURITIES – Elements or compounds whose presence in a material is undesired.

INCONEL – Nickel alloy highly resistant to heat and corrosion, with good mechanical properties, consisting of 80% nickel, 12-14% chromium, the balance being iron.

INERT GAS – A gas that may be used as a shield in welding or heat treatment to prevent oxidation or scaling.

INGOT – A large block of metal that is usually cast in a metal mould and forms the basic material for further rolling and processing.

INGOT IRON – Commercially pure open hearth iron.

INSULATING MATERIALS (electrical) – Materials which offer a very large resistance to flow of current and for that reason they are used to keep the current in its proper path along the conductor.

INOCULATED IRONS – Inoculated irons are high strength irons of such composition that they would ordinarily be white as cast are often inoculated in the ladle with a silicon compound to cause graphitization. Typical agents used are ferrosilicon, calcium silicide, Si-Mn-Zr, or Ca-Mn-Si in crushed form.

INVAR – Nickel iron alloy (35-36% nickel, 0.5% carbon and 0.5% manganese, the remainder being iron) having a very low coefficient of thermal expansion at ordinary temperatures.

ION – An atom, or group of atoms, that has gained or lost one or more outer electrons and thus carries an electric charge. Positive ions, or cat-ions, are deficient in outer electrons. Negative ions or anions, have an excess of outer electrons, thus ion is electrostatically charged.

IRIDIUM 192 – A radio isotope with a half-life of 74 days and 12 dominant characteristic gamma radiation energies ranging from 0.14-0.65 MeV. It is suitable as a gamma radiation source, mostly in radiography.

IRON – Silver white metallic element, symbol Fe, and melting point 1535°C. Pure iron consists of homogenous crystal grains generally referred to as ferrite.

IRON (wrought) – Malleable iron produced from molten pig iron by a working or puddling process which removes the impurities.

INNER RACE – In a bearing assembly, the part that connects a rotating shaft to the bearing.

IGNITION TEMPERATURE – The temperature at which the heat that is generated by the reaction between air and fuel vapour, is faster than that is lost to the surroundings, and combustion thus becomes self propelling. Below this point, the gas air mixture will not burn freely.

IGNITION QUALITY OF DIESELS – is indicated by cetane number. It is the percentage of cetane by volume, in a mixture of cetane (C16 H34) and alpha methyl naphthalene which will exhibit the same ignition characteristic of the fuel under test when tested in a standard engine, under a set of standard test conditions.

INCINERATION – The controlled process in which the combustible solid, liquid or gaseous wastes are burned and changed into non-combustible gases.

INCINERATOR – Any furnace used in the process of burning waste for the primary purpose of reducing the volume of the waste by removing combustible matter.

INDUCED DRAFT FAN – The fan that draws the gases out of the furnace by creating a partial vacuum on the suction side of the fan.

INFRARED GAS ANALYZER – A non-dispersive infrared gas analyzer used to measure very small quantities of the pollutants contained in the exhaust gas.

INTER COOLING – Cooling of air in between the stages of compression so as to reduce the work of compression. The device used for cooling is intercooler.

INTERNAL EFFICIENCY OF A TURBINE – Ratio of work (power) delivered to the rotor of the turbine by the gaseous medium compared with the ideal energy available for work (power) from the medium in expanding through the same pressure range.

ISENTROPIC EFFICIENCY – Ratio of work to compress isentropically to the actual work to compress. Also the ratio of isentropic temperature rise to the actual temperature rise.

INDUCTION HARDENING – Heating the surface of cast iron or tool steel by means of electromagnetic currents followed by a quench.

IDLE SPEED – The speed at which an engine runs without load when the accelerator pedal is released.

I HEAD ENGINE – An overhead valve (OHV) engine with the valves in the cylinder head.

IMPELLER – Finned wheel that produces pressure and flow when spun in an enclosed housing of oil pump or water pump.

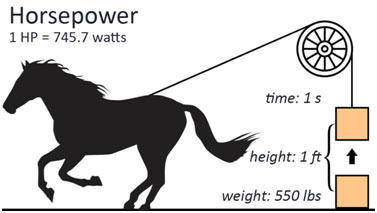

INDICATED HORSE POWER (IHP) – The power produced within the engine cylinders before deducting any frictional loss.

INERTIA – Tendency of a stationary object to resist movement or tendency of a moving object to continue moving in same direction.

IN LINE ENGINE – An engine in which all engine cylinders are in a single row, or line.

INTAKE MANIFOLD – is a casting attached to the cylinder head in the case of a overhead valve engine or to the cylinder block in the case of a side valve engine. Through the intake manifold fresh charge enters the cylinders.

INTAKE STROKE – The piston stroke from TDC to BDC during which the intake valve is open and the cylinder receives a charge of air fuel mixture in a SI engine or air alone in a CI engine.

INTAKE VALVE – The valve that opens to permit fresh charge to enter the cylinder on the intake stroke.

INTERNAL COMBUSTION ENGINE (IC engine) – An engine in which the fuel is burnt inside the engine.

INDICATING INSTRUMENTS – The instruments that provide visual observation of readings, such as pressure gauges, draft gauges, fuel oil meters and thermometers for fuel, feed water and flue gas temperatures etc.

INDICATOR – A sensitive instrument which shows slight variations when testing the trueness, or alignment of a workpiece, fixture or machine part such as a milling vice. Dial indicators may be graduated to read small linear variations.

INSIDE VERNIER CALIPER – is intended mainly for checking internal dimensions, such as the diameter of bores, and so on. Vernier protractor is used for measuring angles accurately.

IDLER GEARS – A gear or gears placed between driver and driven gears when the distance between the driver and driven gears would require too exceptionally large gears. These gears have no effect on the speed or ratio between the driver and driven gears.

INDEPENDENT CHUCK – A three jaw chuck, in which each of, the jaws may be moved independently of the other two.

INDEX CRANK – The crank handle of an index or dividing head used for turning the spindle through a full turn or fractional part of a turn. A pin on the crank fits into the holes of the index plate.

INDEX PLATE – A thin circular plate having various circles of holes. It is attached to the index head and used for obtaining fractional parts of a turn of the index crank. A set of three or more index plates may be furnished for an index head.

INTERMEDIATE GEAR – An idler or loose gear on a stud for transmitting power between a driver and a driven gear.

INVOLUTE GEAR TOOTH – A curved tooth generated by unwinding a string from a cylinder to form the curve.

INTERCOOLER – Heat exchanger for cooling the air between the stages of compression.

INTERNAL COMBUSTION ENGINE – An engine that burns fuel within the cylinder itself as a means of developing power.

INTERNAL GRINDER – Machine used to finish internal surfaces such as engine cylinders, ball bearing races, and similar work that require excellent accuracy and high finish.

INDUSTRIAL TRUCK – A self powered, individually operated conveyance for moving materials or persons.

IMPACT TEST – A test in which small notched specimens are broken in Izod-Charpy machine. This test determines the notch toughness of a metal.

INCLUSIONS – Impurities, usually oxides, sulphides, silicates and similar compounds, retained from the ore or from processing.

INFRARED RADIATION – Electromagnetic energy with wave lengths from 770 to 1200 manometers.

ISOTROPY – Quality of having identical properties in all directions.

IMPACT EXTRUSION – In this process, a slug of metal is placed on a solid bottom die, and the impact of the punch causes the metal to flow back over the punch, which has a uniform section, slightly relieved.

INDEXING – Rotation of a workpiece by small uniform amounts, with or without the aid of change wheels, mainly in connection with milling operation.

INTERNAL GRINDING – Mechanical grinding of the internal bores of gears, bushes and wide variety of machine parts and articles of specialized character.

IMPULSE – Time integral of the impulsive force acting on a body.

IMPULSIVE FORCE – Force that acts on a body for an extremely short interval of time and makes the body to move. Occur in collisions, in explosions, in the striking of a nail by a hammer or of a pile by a tup or monkey.

INERTIA GOVERNOR – Governor in which the position of the flyballs are affected by the rate of change of speed of the governor shaft.

INSTANT CENTRE – (1) A point in one body about which another body is rotating either permanently or at the instant (2) A point common to two bodies having the same linear velocity in both magnitude and direction in each.

INTERMITTENT MOTION MECHANISM – A linkage which converts continuous motion into intermittent motion (e.g., indexing mechanism).

INVOLUTE – The locus of a point on a straight line which rolls, without slipping, on the circumference of a circle, or alternatively the locus of a point on the chord which is held taught and unwound from a cylinder.

INVOLUTE TEETH – The outline of a tooth traced out by a point on a chord unwrapped from a circle (known as base circle).

ISOCHRONISM OF GOVERNOR – A governor is said to be isochronous, if , neglecting friction, the equilibrium speed is the same for all radii of the flyballs.

ICE MAKING CAPACITY – Ability of a refrigerating system to make ice, starting with water at room temperature.

INDICATED HORSE POWER – Rate at which work is usefully expended in the compressor i.e., actually utilized in compressing the refrigerant vapour and expelling it from the compressor.

INDUCTIVE DEVICE – Designed to convert electrical energy to magnetic and then to mechanical energy.

INSULATION – Any material that effectively slows down the transfer of heat.

INSULATORS – Materials that normally deter the flow of electrons.

IDLE MIXTURE – The air fuel mixture supplied to an engine during idle. The mixture is usually rich. The idle mixture screw(s) are sometimes adjusted as a part of tune up.

IDLE MIXTURE ADJUSTMENT SCREW – The adjustment screw in some carburettors, that can be turned in or out to vary the quality of the idle mixture.

IDLE SYSTEM – In the carburettor, the passages through which fuel is fed when the engine is idling.

IGNITION (spark) – In an engine, the act of spark in starting the combustion process in the cylinder.

IGNITION ADVANCE – To set the ignition timing, so that a spark occurs earlier or more degrees before TDC.

IGNITION COIL – That part of the ignition system which acts as a transformer to step up the battery voltage to many thousand volts, the high voltage surge then produces a spark at the spark plug gap.

IGNITION DISTRIBUTOR – That part of the ignition system, which opens and closes the circuit to the ignition coil with correct timing and distributes to the proper spark plugs the resulting high voltage surges from the ignition coil.

IGNITION SWITCH – The switch in the ignition system which is operated with a key to open and close the ignition primary circuit.

IGNITION SYSTEM – The part of the electrical system that provides high voltage sparks to the engine cylinder to fire the compressed air fuel mixture, consisting of a voltage source, timing device, capacitor, ignition coil, secondary wiring and spark plugs.

IGNITION TIMING – is the crank angle at which spark occurs relative to the top dead center, during compression stroke.

INTAKE MANIFOLD (SI engine) – The part of the engine that provides a series of passages from the carburettor to the engine cylinders through which air fuel mixture can flow.

INTAKE STROKE – The piston movement from TDC to BDC that occurs as the intake valve opens. This movement causes entry of fresh charge.

INCRUSTATION – A coating over, the coating, being commonly known as scale.

INDUSTRIAL BOILER – A stationary water tube steam generator, in which some of the steam is produced in a convective tube bank.

INJECTOR – An instrument for forcing water into a boiler against the boiler pressure by means of a steam jet.

INTERMITTENT BLOW DOWN – Blow down that is taken from the bottom of the mud-drum, water wall headers, or lowest point in the circulation system, at regular intervals.

INTERNALLY FIRED BOILER – Boiler in which the furnace is within the shell, being surrounded by water.

INTERNAL TREATMENT – Treating water in the boiler while evaporation is taking place by chemically adjusting or balancing the boiler water to prevent scale formation, corrosion, steam contamination and embrittlement.

IMPULSE – The act of impelling or suddenly driving forward in the same direction as the applied force.

IMPULSE TURBINE – A steam turbine in which the steam is expanded causing pressure drop in nozzles only and the moving blades attached to the rotor merely deflect the steam through an angle. The pressure on the two sides of the blades remains constant.

IMPULSE REACTION TURBINE – A steam turbine in which the steam is expanded both in the fixed blade and the moving blade continuously as the steam passes over them. The pressure drops gradually and continuously over both moving and fixed blades. Often called as REACTION TURBINE.

INTERNAL TURBINE EFFICIENCY – Ratio of the total useful heat drop to the adiabatic heat drop corresponding to the whole pressure drop that occurs. This is the product of stage efficiency and reheat factor.

IDEAL GAS – is one which will obey all the gas laws, under all conditions of temperature and pressure. For an ideal gas, the internal energy and enthalpy are functions of temperature alone.

INDICATED HORSE POWER – The actual power developed or used within a cylinder as calculated from the indicator diagram.

INERT GAS – A gas which under normal conditions does not react with or combine with other substances for example, argon, helium, neon, krypton, xenon.

INTERNAL ENERGY – is the energy arising from the motion and from configuration of the internal particles (atoms and molecules). It is the energy stored in the gas and is used for raising its temperature. v = CvT., Δu = Cv (T2 – T1).

INTRINSIC PROPERTIES – also called intensive properties, are those properties which are independent of the mass of the system. Examples are pressure, temperature and density.

ISENTROPIC PROCESS – which is called reversible adiabatic process is one in which no heat is supplied and work done is at the expense of internal energy. Law followed is Pvγ = constant.

ISOLATED SYSTEM – is a special case of the closed system which will not be influenced by the surrounding. In this system, no mass transfer, no energy transfer occurs. Work and heat cannot cross the boundary of the system.

ISOTHERM – The line drawn through points or areas of similar temperature.

ISOTHERMAL EXPANSION or COMPRESSION – The expansion or compression of a gas at constant temperature, that is with the gas temperature remaining the same during the process.

INDIRECT DRIVE GEARBOX – A gearbox where power is transferred from clutch to input shaft and from that to output shaft. Output shaft has a sprocket mounted on one end.

INPUT SHAFT – Shaft of a gearbox which carries power into gearbox.

Clutch assembly is mounted on gearbox input shaft.

INTAKE PORT – In a two stroke engine, the passage way that allows the air fuel oil mixture to travel from the carburettor into the crankcase, located on the lower half of the cylinder opposite from the exhaust port on all but rotary valve engine.

INTAKE TIMING – Amount of time, two stroke cycle engine intake port is open, expressed in crankshaft degrees or piston position.

INTERNAL COOLING – Engine cooling provided by oil, fuel mixtures, and valve overlap.

INERT GAS – A gas which does not normally combine chemically with the base metal or filler metal.

INTERMITTENT WELD – A weld in which the continuity is broken by recurring unwelded spaces.