A powder can be defined as a finely divided particulate solid.

· Engineering powders include metals and ceramics.

· The main purpose of powder testing is to ensure whether or not the powder is suitable for further processing.

Principle characteristics of metal powders are

1. Chemical composition (purity)

2. Particle size and its distribution

3. Particle shape

4. Particle porosity

5. Particle microstructure

6. Specific characteristics like -Specific surface, apparent density, tap density, flow rate, green density and green strength

Chemical composition (Purity)

It is the term to understand the type and percentage of impurities that the powder contains.

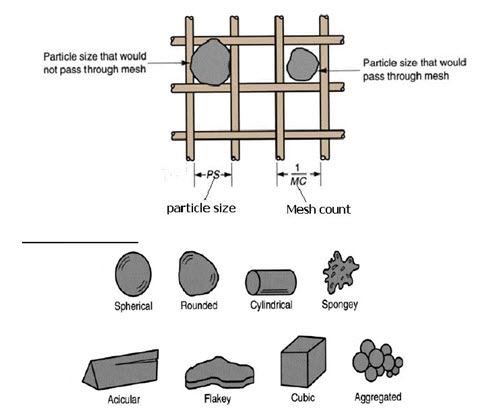

Several of the possible (ideal) particle shapes in powder metallurgy

Particle size and its distribution

The particle size is defined by the mesh count. Mesh count refers to the number of openings per linear inch of mesh.

Particle shape

Various shapes of metal powders observed according to the method of production

Particle porosity

•Ratio of the volume of the pores (empty spaces) in the powder to the bulk volume

•Porosity increases stress in the part so it is not desirable.

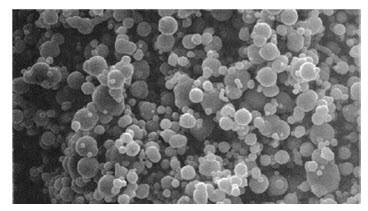

Particle microstructure

•For observation of microstructure, the powder metallurgy part is first polished, then etching of the surface similar to the dye penetrant method is done which will show the microstructure of the powder metallurgy part.

micro structure of particles