a)  Test results generally depend upon the dimensions of the specimen being tested. Test results in a form that can be applied to members of any size we convert the test results to stresses and strains.

Test results generally depend upon the dimensions of the specimen being tested. Test results in a form that can be applied to members of any size we convert the test results to stresses and strains.

i. Nominal stress ( conventional stress and engineering stress ) – initial area of the specimen is used

ii. True stress – actual area of the bar at the cross section where failure occurs

iii. Nominal strain – initial gage length is used

iv.  True strain (or natural strain) – actual distance between the gage marks

True strain (or natural strain) – actual distance between the gage marks

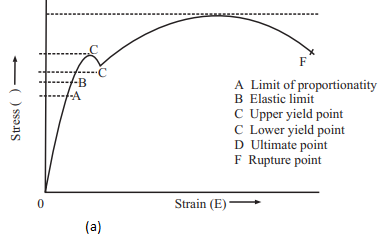

b. Metals such as structural steel that undergo large permanent strains before failure are classified as ductile.

c. Materials that fail in tension at relatively low values of strain are classified as brittle.