1. How is cutting operation carried out?

The work piece is stressed beyond its ultimate strength and cut-off into two pieces.

2. List out the various cutting operations.

a. Blanking

b. Punching

c. Shearing

d. Parting off

3. Mention the three different ways of working sheet metal in presses.

a. Shearing

b. Bending

c. Drawing

4. Classify sheet metal operations

a. Cutting operations

b. Forming operations

5. State the advantages of press working operations.

a. Material economy

b. High productivity

c. Uniformity of parts

d. Use of less labor.

6. What are the applications of press working operations?

a. Electronic appliances

b. Steel furniture

c. Coach building

d. Automobile industry

7. Name some types of forming operations.

a. Bending

b. Drawing

c. Squeezing

d. Embossing

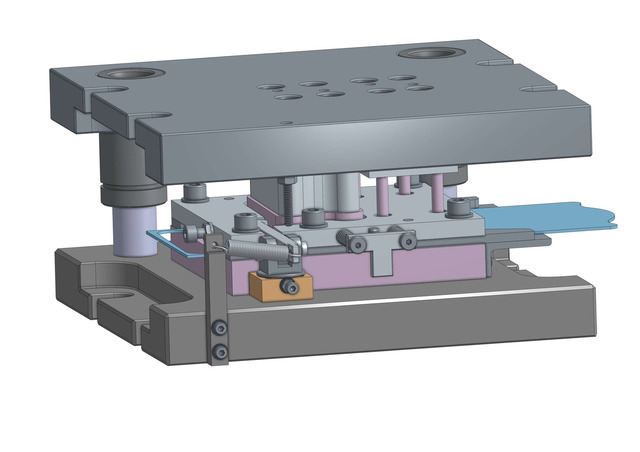

8. List out the press working terminology.

a. Base

b. Bolster plate

c. Die holder

d. Die

e. Stripper

f. Punch

g. Pitman

h. Stroke

i. Guide pin

j. Back up plate

9. When will be hydraulically driven presses used?

Whenever large force and slow speed are required in forming, pressing and drawing operation, hydraulically driven presses are used.

10. How will you select the proper material for press tools?

a. Hardness

b. Compressive strength

c. Bending strength

d. Toughness

11. What factors are considered for selecting an appropriate press for a given job?

a. Force required to be cut the metal b. Die space

c. Size and type of die d. Stroke length

e. Shut height

f. Type of operation

g. Speed of operation

12. List down the material used for press working operations.

a. Mild steel

b. Stainless steel

c. Brass

d. Copper

e. Aluminum

f. Hard rubber

g. Fiber

13. What is a progressive die? When should a progressive die be used?

A die which is used to perform two or more operations at different stages every time when the ram descends is called progressive die. It is mainly used where the accuracy of the products is maintained.

14. Explain the function of bolster plate in press tool.

The bolster plate is the thick plate mounted on the base. It is used for locating and supporting the die assembly. It is usually 5 to 12.5 mm thick plate.

15. What are the methods of holding pilots?

a. Direct pilots

b. Indirect pilots

16. What are the types of stock stop?

a. Lever or latch type

b. Automatic stop

c. Shoulder stop

d. Starting stop

17. State the function of a knockout.

The function of knockout is to eject or remove the work piece from within the die cavity as the work piece may adhere in the die cavity due to friction.

18. What is the purpose of pilot?

Pilot is a locating pin chamfered on the front end to facilitate catching and entering the work piece.

19. List down the various methods of arranging guide pins in the die set.

a. Back-post design

b. Centre-post design

c. Diagonal-post design

d. Four-guide post design

20. What are the types of die set?

a. Precision die set

b. Commercial die set