Portland cement is a closely controlled chemical combination of calcium, silicon, aluminum, iron and small amounts of other compounds, to which gypsum is added in the final grinding process to regulate the setting time of the concrete. Some of the raw materials used to manufacture cement are limestone, shells, and chalk or marl, combined with shale, clay, slate or blast furnace slag, silica sand, and iron ore. Lime and silica make up approximately 85 percent of the mass The term “Portland” in Portland cement originated in 1824 when an English mason obtained a patent for his product, which he named Portland Cement. This was because his cement blend produced concrete that resembled the color of the natural limestone quarried on the Isle of Portland in the English Channel. Different types of Portland cement are manufactured to meet different physical and chemical requirements for specific purposes.

Common Examples

Structural clay products Brick, sewer pipe, roofing tile, clay floor and wall tile (i.e., quarry tile), flue linings

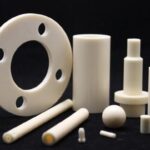

Whitewares Dinnerware, floor and wall tile, sanitaryware, electrical porcelain, decorative ceramics

Refractories Brick and monolithic products are used in iron and steel, non-ferrous metals, glass, cements, ceramics, energy conversion, petroleum, and chemicals industries

Glasses Flat glass (windows), container glass (bottles), pressed and blown glass (dinnerware), glass fibers (home insulation), and advanced/specialty glass (optical fibers) Abrasives Natural (garnet, diamond, etc.) and synthetic (silicon carbide, diamond, fused alumina, etc.) abrasives are used for grinding, cutting, polishing, lapping, or pressure blasting of materials

Cements Used to produce concrete roads, bridges, buildings, dams, and the like