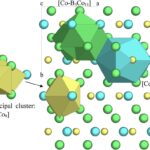

Case of lead-tin alloys, A layered, eutectic structure develops when cooling below the eutectic temperature. Alloys which are to the left of the eutectic concentration (hipoeutectic) or to the right (hypereutectic) form a proeutectic phase before reaching the eutectic temperature, while in the solid + liquid region. The eutectic structure then adds when the remaining liquid is solidified when cooling further. The eutectic microstructure is lamellar (layered) due to the reduced diffusion distances in the solid state. To obtain the concentration of the eutectic microstructure in the final solid solution, one draws a vertical line at the eutectic concentration and applies the lever rule treating the eutectic as a separate phase.

Posted inMaterial Science

Development of microstructure in eutectic alloys

Suresh Kumar is a passionate mechanical engineer with deep expertise in design, thermodynamics, manufacturing, and automation. With years of experience in the industry, they simplify complex engineering principles into practical insights for students, professionals, and enthusiasts. This blog serves as a hub for exploring cutting-edge innovations, fundamental concepts, and real-world applications in mechanical engineering.

Post navigation

Previous Post

Binary Eutectic Systems

Binary Eutectic SystemsNext Post

Eutectoid and Peritectic Reactions