Hydraulic Brake is an arrangement of braking mechanism which uses brake fluid, typically containing ethylene glycol, to transfer pressure from the controlling unit, which is usually near the operator of the vehicle, to the actual brake mechanism, which is usually at or near the wheel of the vehicle.

The most common arrangement of hydraulic brakes for passenger vehicles, motorcycles, scooters, and mopeds, consists of the following:

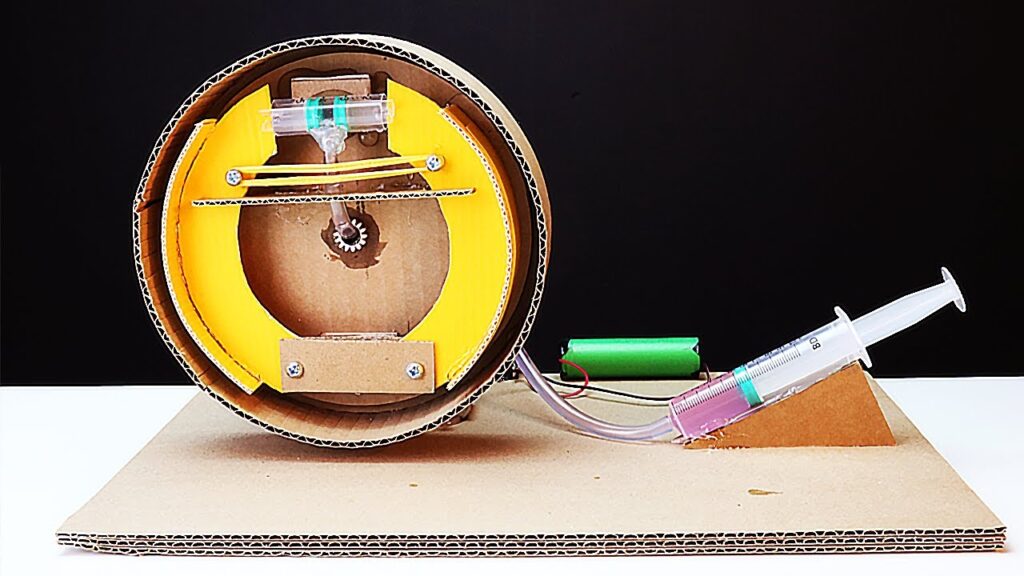

a) Brake pedal or lever

b) A push rod (also called an actuating rod)

c) A master cylinder assembly containing a piston assembly (made up of either one or two pistons, a return spring, a series of gaskets/ O-rings and a fluid reservoir)

d) Reinforced hydraulic lines

e) Brake caliper assembly usually consisting of one or two hollow aluminum or chrome-plated steel pistons (called calliper pistons), a set of thermally conductive brake pads and a rotor (also called a brake disc) or drum attached to an axle.

At one time, passenger vehicles commonly employed drum brakes on all four wheels. Later, disc brakes were used for the front and drum brakes for the rear. However, because disc brakes have shown a better stopping performance and are therefore generally safer and more effective than drum brakes, four-wheel disc brakes have become increasingly popular, replacing drums on all but the most basic vehicles. Many two-wheel vehicles designs, however, continue to employ a drum brake for the rear wheel.