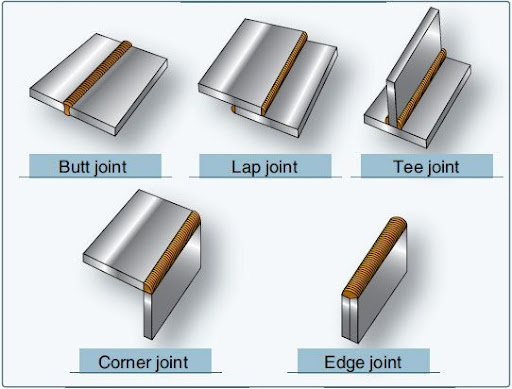

There are five different types of welded joints for bringing two parts together for joining. Five types of welded joints are butt joint, corner joint, lap joint, tee-joint and edge joint.

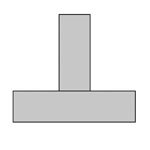

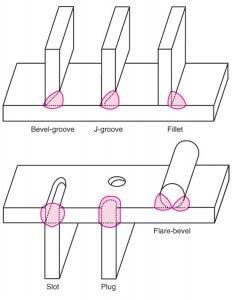

Tee Welding Joint

Tee welding joints are formed when two members intersect at a 90° angle which makes the edges come together in the center of a plate or component. Tee Joints are considered a type of fillet weld, and can also be made when a pipe or tube is welded onto a base plate. Extra care is required to ensure effective penetration into the roof of the weld.

Welding Styles Used To Create T-Joints

· Plug weld

· Fillet weld

· Bevel-groove weld

· Slot weld

· Flare-bevel-groove weld

· J-groove weld

· Melt-through weld

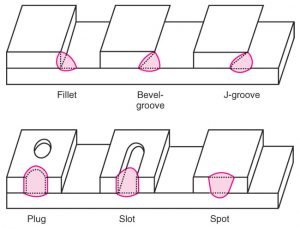

Lap Welding Joint

Lap welding joints are used most often to joint two pieces with differing thicknesses together. Also considered a fillet type, the weld can be made on one or both sides. A Lap Joint is formed when 2 pieces are placed in an over lapping pattern on top of each other.

Welding Styles Used To Create Butt Joints:

· Slot weld

· Plug weld

· Bevel-groove weld

· Spot weld

· Flare-bevel-groove weld

· J-groove weld

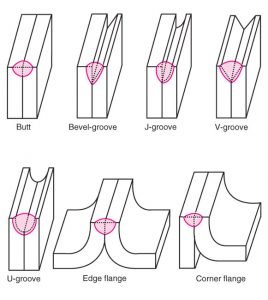

Edge Welding Joint

Edge welding Joints are often applied to sheet metal parts that have flanging edges or are placed at a location where a weld must be made to attach to adjacent pieces. Being a groove type weld, Edge Joints, the pieces are set side by side and welded on the same edge. For heavier applications filler metal is added to melt or fuse the edge completely and to reinforce the plate.

Welding Styles Used To Create Edge Joints:

· Bevel-groove weld

· Square-groove weld or butt weld

· J-groove weld

· V-groove weld

· Edge-flange weld

· U-groove weld

· Corner-flange weld

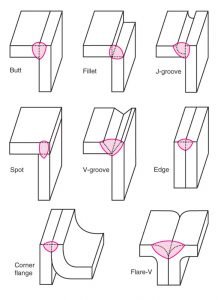

Corner Welding Joint

Being one of the most popular welds in the sheet metal industry the Corner welding joint is used on the outer edge of the piece. This weld is a type of joint that comes together at right angles between two metal parts to form an L. These are common in the construction of boxes, box frames and similar fabrications.

Welding Styles Used To Create Corner Joints:

· Spot weld

· Fillet weld

· V-groove weld

· Square-groove weld or butt weld

· U-groove weld

· Bevel-groove weld

· Flare-V-groove weld

· J-groove weld

· Corner-flange weld.

· Edge weld

Butt Welding Joint

Being the universally accepted method for attaching a pipe to itself it’s also used for valves, flanges, fittings, and other equipment. A butt welding joint is also known as a square grove weld. It’s the easiest and probably the most common weld there is. It consists of two flat pieces that are side by side parallel. It’s a very affordable option.

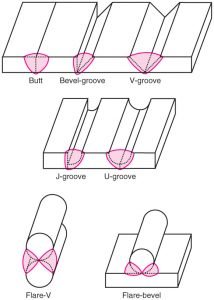

Welding Styles Used To Create Butt Joints:

· Bevel-groove butt weld

· Square-groove butt weld

· V-groove butt weld

· U-groove butt weld

· J-groove butt weld

· Flare-bevel-groove butt weld

· Flare-V-groove butt weld