TQM is mainly concerned with continuous improvement in all work, from high level strategic planning and decision-making, to detailed execution of work elements on the shop floor. It stems from the belief that mistakes can be avoided, and defects can be prevented. It leads to continuously improving results, in all aspects of work, as a result of continuously improving capabilities, people, processes and technology.

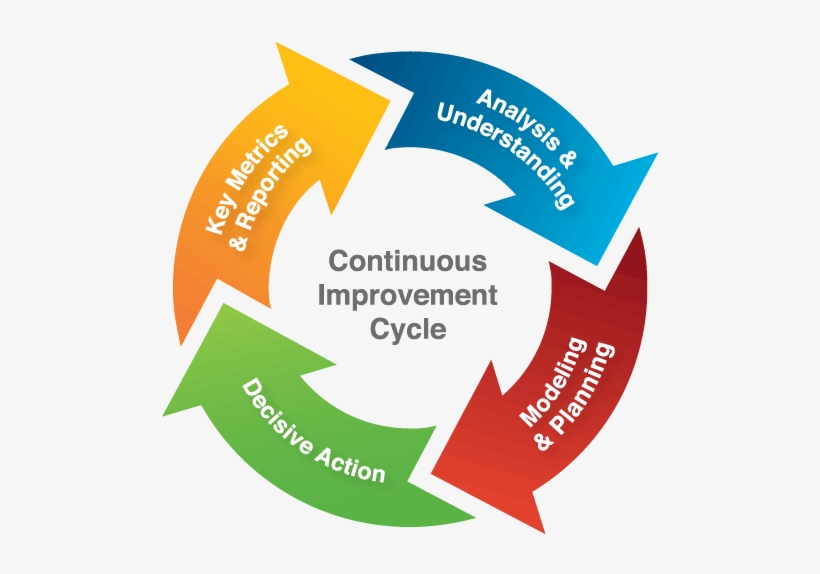

Continuous improvement must deal not only with the improving results, but more importantly with improving capabilities to produce better results in the future. The five major areas of focus for capability improvement are; demand generation, supply generation, technology, operations and people capability (Sivankalai and Yadav, 2012).

A central principle of TQM is that mistakes may be made by people, but most of them are caused, or at least permitted, by faulty systems and processes. This means that the root cause of such mistakes can be identified and eliminated, and repetition can be prevented by changing the process (Gilbert, 1992).

There are three major mechanisms of prevention: 1. Preventing mistakes (defects) from occurring (mistake-proofing or pokayoke). 2. Where mistakes can’t be absolutely prevented, detecting them early to prevent them being passed down the value-added chain (inspection at source or by the next operation). 3. Where mistakes recur, stopping production until the process can be corrected, to prevent the production of more defects. (Stop in time).