Many objects consist of more parts or elements. From reliability point of view, an element is any component or object that is considered in the investigated case as a whole and is not decomposed into simpler objects. An element can be a lamp bulb, the connecting point of two electric components, a screw, an oil hose, a piston in an engine, and even the complete engine in a diesel locomotive. Also, the individual operations or their groups in a complex manufacturing or building process can be considered as elements. An example of a simple system is an electric lamp made by a light bulb, socket, switch, wires, plug, and the lamp body. An extremely complex system is an aircraft, containing tens of thousands of mechanical, hydraulic, or electric elements. Each of them can fail. This increases the probability that the whole system fails. The resultant reliability depends on the reliability of the individual elements and their number and mutual arrangement. A suitable arrangement can even increase the reliability of the system. In this chapter, important cases will be shown together with the formulas for the calculation of resultant reliability. Two basic systems are series and parallel, and their combinations are also possible.

Series system

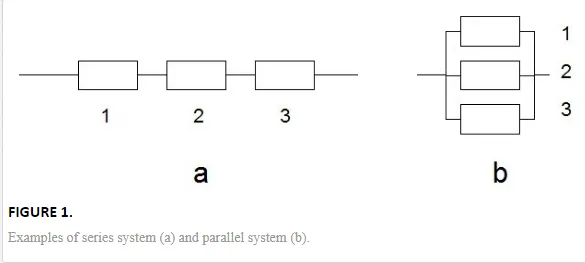

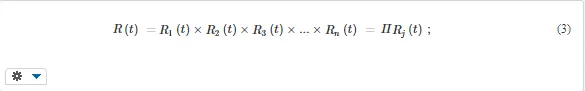

From reliability point of view, a series system (Fig. 1a) is such, which fails if any of its elements fails. For example, a motorcycle cannot go if any of the following parts cannot serve: engine, tank with fuel, chain, frame, front or rear wheel, etc., and, of course, the driver. All these elements are thus arranged in series. Elements are also screws and many other things. If failure of any component does not depend on any other component, the reliability of the system is obtained simply as the product of the reliabilities of individual elements,

A practical conclusion is that “the reliability of a series system is always lower than the reliability of any of its components”.

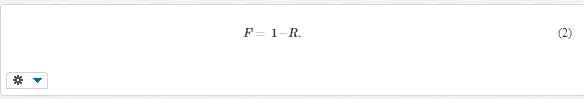

The probability of failure is complementary to reliability, i.e.

The probability of failure is complementary to reliability, i.e.

The characteristic features of series arrangement will be shown on several examples.

Example 1

The resultant reliability of two components is R = R1 × R2. For example, if F1 = 0.1 and F2 = 0.2, then R1 = 0.9 and R2 = 0.8 and R = 0.9 × 0.8 = 0.72. This is less than the reliability of the weaker component no. 2. The probability of failure has increased to 1 – 0.72 = 0.28, i.e. more than the failure probability F2.

Example 2

The reliability of a series system with three elements with R1 = 0.9, R2 = 0.8, and R3 = 0.5 is R = 0.9 × 0.8 × 0.5 = 0.36, which is less than the reliability of the worst component (R3 = 0.5). This reminds of the well-known saying “The chain is as weak as its weakest link“ (which, however, does not consider that several components can fail simultaneously).

Example 3

The influence of the number of elements (and thus complexity of the system) can be illustrated on several systems where all components have the same probability of failure F1 = 0.02; the corresponding reliability R1 = 0.98. What will be the reliability of a system composed of (a) 2 components, (b) 10 components, (c) 50 components, and (d) 200 components?

Solution: (a) R = R1 × R1 = 0.982 = 0.960; (b) R = R110 = 0.9810 = 0.817; (c) R = R150 = 0.9850 = 0.364; and (d) R= R1200 = 0,98200 = 0.0176.

One can see that the drop of reliability is significant especially for high numbers of components. Although one component has relatively high reliability (98%), a system with 200 such parts is practically unable to work, as it has reliability lower than approximately 2% and probability of failure 98%! Complex large systems must therefore be assembled from very reliable elements.

Until now, we have assumed that the reliability of individual parts does not change with time. If it varies, Equation (1) changes to

the resultant probability of failure is obtained as

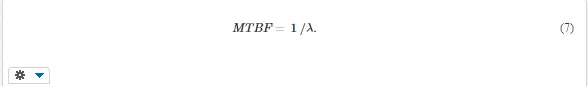

The reliability of components is often characterized by failure rate λ. If the failure rate may be assumed constant (especially in systems containing many elements), the decrease of reliability with time is exponential, R(t) = exp (– λt), and Equation (3) changes to

The distribution of times to failure of such system is again exponential, with the resultant failure rate equal the sum of individual failure rates,

This means that ”the failure rate of a series system is always higher (and the mean time between failures shorter) than that of individual components, and the reliability R(t) decreases with time faster”.

The mean time between failures is

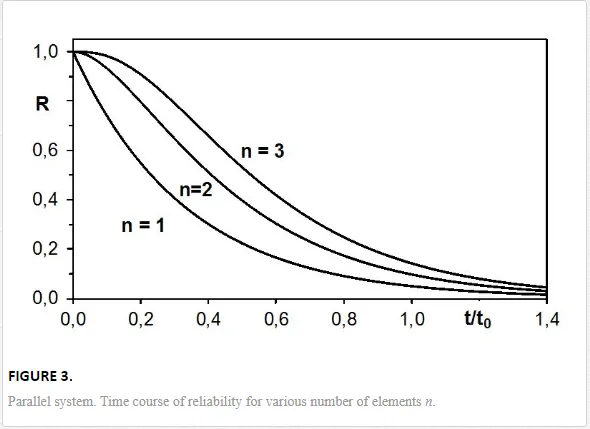

The decrease of reliability with time is illustrated in Figure 2 for several systems with different numbers of elements. One can see a very fast drop of reliability in systems with many components. This must be accounted for if guaranteed operation of a complex object during certain time is demanded. This issue will be treated in detail later.

Parallel system

A parallel system (Fig. 1b) is such, which fails only if all its parts fail. An example is a four-cylinder engine. It will fail only if all four cylinders are unable to run. If one, two, or even three cylinders do not work, the fourth one is still able to put the car into motion (though with significantly reduced power).

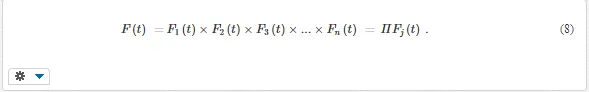

The probability of a simultaneous occurrence of mutually independent events equals the product of individual probabilities. In parallel systems, the resultant probability of failure is thus calculated as

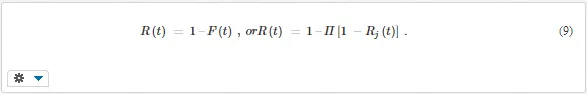

Reliability is complementary to probability of failure, i.e.

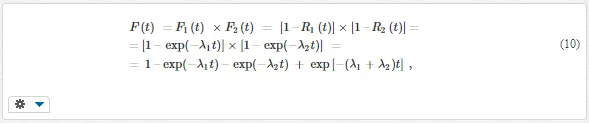

For example, if two components are arranged in parallel, each with reliability R1 = R2 = 0.9, that is, F1= F2 = 0.1, the resultant probability of failure is F = 0.1 × 0.1 = 0.01. The resultant reliability is R = 1 – 0.01 = 0.99. The probability of failure has thus dropped 10 times. This feature is sometimes used for reliability increasing by using redundant parts (see later). If the reliability of elements is characterized by failure rates, the situation is more complex than in a series system, even if the failure rates of the individual elements are constant. For the simplest case of two components, with R1(t) = exp(-λ1t) and R2(t) = exp(-λ2t)

and

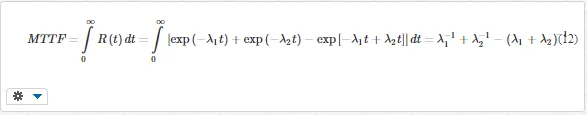

The distribution is no more exponential and the failure rate is not constant. The mean time to failure is

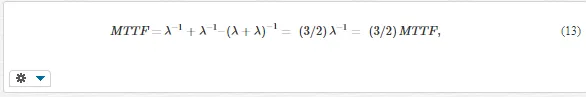

For identical components, with λ1 = λ2 = λ,

i.e. by 50% longer than the mean time to failure of individual components. The solution for parallel systems with more elements can be obtained in similar way. However, it is much more complicated. Analytical solutions exist only in very simple cases; more effective is the use of the Monte Carlo simulation method, explained in Chapter 15. Generally, the reliability of parallel arrangement can be characterized as follows:

“The probability of failure-free operation of a system with several parallel elements is always higher than that of the best element in the system.” The situation is depicted in Figure 3. Also, the mean time to failure of a parallel system is always longer than that of any of its parts. For this reason, parallel arrangement is sometimes used to increase reliability (see further).

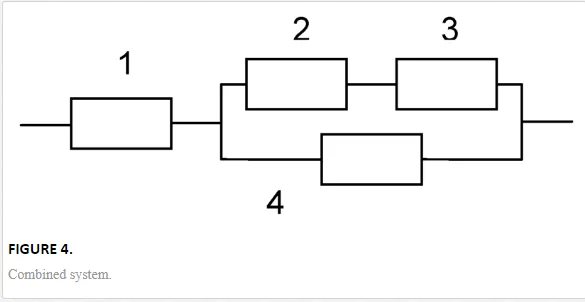

Combined arrangement

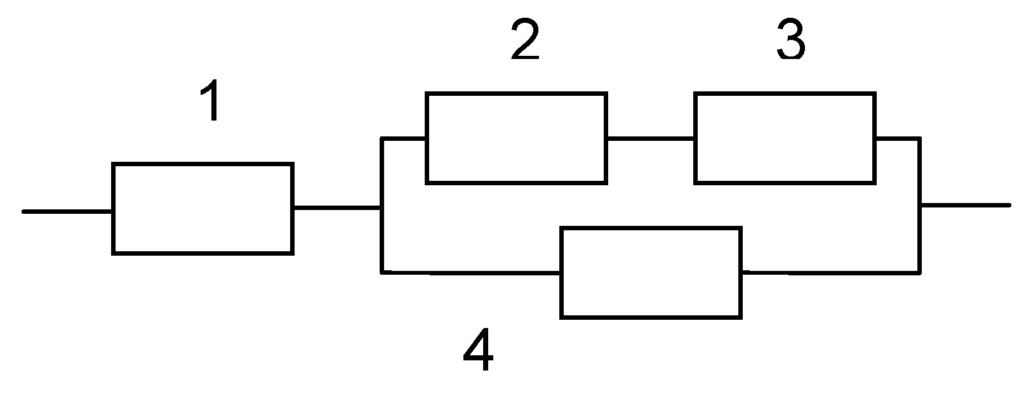

In some systems, series and parallel arrangements of elements appear together (Fig. 4). The resultant reliability can be found using step-by-step solution and gradual simplification. The group of elements arranged in series is replaced by one element with equivalent reliability parameters. Parallel elements can sometimes also be replaced by an equivalent element, and so on. The situation is easier if the time dependency of reliabilities does not need to be considered. Unfortunately, if reliability is characterized by failure rates, the failure rate for parallel arrangement is not constant and no simple and accurate analytical solutions exist, only approximate. Better results can be obtained using numerical simulation methods.

Redundancy

Reliability can be increased if the same function is done by two or more elements arranged in parallel. This is called redundancy. Two kinds of redundancy can be distinguished: structural and algorithmic. Structural redundancy uses more components for the same purpose. Examples include dual-circuit brakes in modern cars, a reserve water pump in a power plant, joining of two load-carrying parts using more rivets than necessary for safe transfer of the load, a spare electric generator to ensure safe power supply in a hospital, or a reserve electric line. Redundancy can be active (the parallel elements work or are loaded simultaneously) or standby. In the latter case, only one element is loaded or works, whereas the second (third, etc.) redundant element is switched on just if the first one has failed. The advantage of standby redundancy is that only one component is loaded and exposed to wear or other kinds of deterioration. A disadvantage is that such arrangement usually needs a switch or similar item, which increases the costs and can also contribute to the unreliability of the system.

The second case is algorithmic redundancy. This means the repetition of some operations, for example measurement or check for defects in some kinds of nondestructive control, such as X-ray or ultrasonic revealing of internal defects in castings or fatigue cracks in airframes or wings, as well as the proofreading of a paper for finding errors. Algorithmic redundancy is commonly used in the transmission of signals and information, from the simple addition of parity bits (check digits) to complex systems for safe information coding.

Reliability allocation

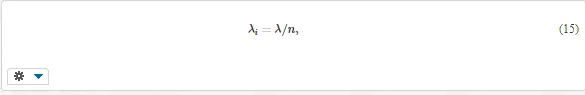

Until now, we determined the resultant reliability of a system composed of more components. In the design of complex systems, an opposite problem appears: what should be the reliabilities of individual parts so that the reliability of the whole system is equal to some demanded value (or better)? Several methods of reliability allocation were proposed. The simplest one for series systems uses equal apportionment, which distributes the reliability uniformly among all members. If the resultant reliability should be R and the system consists of n components in a series, each of the reliability Ri, then it follows from Equation (1) that R = Rin, so that every single element should have the reliability

If failure rates are considered, then the failure rate λi of every element should be

where λ is the demanded failure rate of the system.

Also other apportionments are possible. Not always has each available component the reliability Ri or λicorresponding exactly to Equation (14) or (15). Such values can serve as a guide for finding the parameters so that the resultant reliability (1), (3), or (6) fulfills the requirements. In the reliability allocation, other criteria can also be considered, such as the importance of individual parts.

Example 4

A system consists of three parallel components (Fig. 1b) with probabilities of failure (during a certain, unspecified time): F1 = 0.08, F2 = 0.20, and F3 = 0.20. Calculate the resultant probability of failure (F) and of failure-free operation (R). Assume that the components are independent.

Solution. In parallel systems, F = F1 × F2 × F3 = 0.08 × 0.20 × 0.20 = 0.0032. R = 1 – F = 1 – 0.0032 = 0.9968. (Compare the results with the failure probabilities of individual components!)

Example 5

Calculate the mean time to failure and failure rate of a system consisting of four elements in a series (like in Fig. 1a). The individual elements have exponential distribution of the time to failure with failure rates λ1 = 8 × 10– 6 h–1, λ2 = 6 × 10– 6 h–1, λ3 = 9 × 10– 6 h–1, and λ4 = 2 × 10– 5 h–1. Calculate the probability of failure (in %) during the time t = 500 hours of operation.

Solution.

Example 6

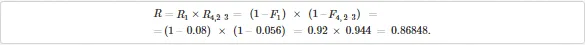

Calculate the resultant probability of failure (F) and failure-free operation (R) for a combined series-parallel system (Fig. 4). Assume that the components are independent. The failure probabilities of individual elements are: F1 = 0.08, F2 = 0.30, F3 = 0.20, and F4 = 0.10.

Solution. The system must be solved step-by-step. First, the reliability of elements 2 and 3 in a series is calculated: R2–3 = R2 × R3 = (1 – F2) × (1 – F3) = (1 – 0.3) × (1 – 0.2) = 0.7 × 0.8 = 0.56. The probability of failure is complementary to reliability, so that F2–3 = 1 – R2–3 = 1 – 0.56 = 0.44. Then, the reliability of this F2–3 group arranged in parallel with element 4 is obtained as F4,2–3 = F4 × F2–3 = 0.10 × 0.56 = 0.056. The resultant reliability of the whole system is obtained as the reliability of component 1 in a series with the subsystem 4,2-3. Here, the reliabilities must be multiplied. The resultant reliability thus is

he resultant probability of failure is F = 1 – R = 1 – 0.86848 = 0.13152 ≈ 0.13.

Example 7

The failure rate of a system of five components arranged in a series should be λ = 2.0 × 10-5 h-1. Determine the failure rate of individual components provided that all can have the same λi. Solution. The resultant failure rate of this series system is λ = λ1 + λ2 + λ3 + λ4 + λ5. For identical components, it is λ = 5λi. The demanded failure rate of each part is λi = λ/5 = 2.0 × 10– 5 / 5 = 4.0 × 10– 6 h-1.