A steam power plant, also known as thermal power plant, is using steam as working fluid. Steam is produced in a boiler using coal as fuel and is used to drive the prime mover, namely, the steam turbine. In the steam turbine, heat energy is converted into mechanical energy which is used for generating electric power. Generator is an electro-magnetic device which makes the power available in the form of electrical energy.

Layout of steam power plant:

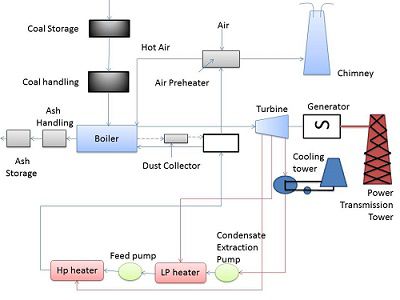

The layout of the steam power plant is shown in figure below. It consists of four main circuits. These are:

● Coal and ash circuit.

● Air and flue gas circuit

● Water and steam circuit and

● Cooling water circuit

Coal and ash circuit:

Coal from the storage yard is transferred to the boiler furnace by means of coal handling equipment like belt conveyor, bucket elevator, etc., ash resulting from the combustion of coal in the boiler furnace collects at the back of the boiler and is removed to the ash storage yard through the ash handling equipment.

Ash disposal :

The indian coal contains 30% to 40% ash. A power plant of 100MW 20 to 25 tonnes of hot ash per hour. Hence sufficient space near the power plant is essential to dispose such large quantities of ash.

Air and flue gas circuit:

Air is taken from the atmosphere to the air preheater. Air is heated in the air preheater by the heat of flue gas which is passing to the chimney. The hot air is supplied to the furnace of the bolier.

The flue gases after combustion in the furnace, pass around the boiler tubes. The flue gases then passes through a dust collector, economizer and pre-heater before being exhausted to the atmosphere through the chimney. By this method the heat of the flue gases which would have been wasted otherwise is used effectively. Thus the overall efficiency of the plant is improved.

Air pollution:

The pollution of the surrounding atmosphere is caused by the emission of objectable gases and dust through the chimney. The air pollution and smoke cause nuisance to people surrounding the planet.

Feed water and steam circuit:

The steam generated in the boiler passes through super heater and is supplied to the steam turbine. Work is done by the expansion of steam in the turbine and the pressure of steam is reduced. The expanded steam then passes to the condenser, where it is condensed.

The condensate leaving the condenser is first heated in a l.p. water heater by using the steam taken from the low pressure extraction point of the turbine. Again steam taken from the high pressure extraction point of the turbine is used for heating the feed water in the H.P water heater. The hot feed water is passing through the economizer, where it is further heated by means of flue gases. The feed water which is sufficiently heated by the feed water heaters and economizer is then fed into the boiler.

Cooling water circuit:

Abundant quantity of water is required for condensing the steam in the condenser. Water circulating through the condenser may be taken from various sources such as river or lake, provided adequate water supply is available from the river or lake throughout the year.

If adequate quantity of water is not available at the plant site, the hot water from the condenser is cooled in the cooling tower or cooling ponds and circulated again.

Advantages of thermal power plants

1. Initial cost is low compared with hydro-plant.

2. The power plant can be located near load center, so the transmission losses are considerably reduced.

3. The generation of power is not dependent on the nature’s mercy like hydro plant.

4. The construction and commissioning of thermal plant requires less period of time than a hydro plant.