This is also a modern high pressure water tube boiler using the forced circulation principle and named after Prof.Loeffler.

Salient features of Loeffler Boiler

The novel feature of the Loeffler Boiler is to evaporate water solely by means of superheated steam. The furnace heat is supplied only to economiser and superheater. In other words, steam is used as a heat absorbing medium.

The major difficulty experienced in La-Mont boiler is deposition of salt and sediment on the inner surfaces of water tubes. The deposition reduces the heat transfer, ultimately, the generating capacity. This difficulty was solved in Loeffler boiler by preventing the flow of water into the boiler tubes. Feed water is evaporated in the drum using part of the superheated steam coming out from the water-heater. Thus only the dry saturated steam passes through the tubes. Poor feed water can, therefore, be used without any difficulty in the boiler, which is great advantage of this boiler.

Working principle of Loeffler Boiler

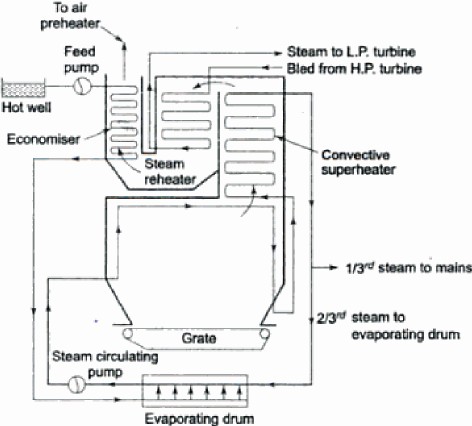

The image shows the outline diagram of Loeffler Boiler.

Economiser

The feed water from the feed tank is supplied to the economiser by feed pump. In the economiser the feed water is made to flow through a number of tubes surrounding which the hot gases leaving the furnace pass over. There is a heat exchange from the hot gases to the feed water, which is preheated in the economiser.

Evaporated Drum

It is housed away from the furnace. It contains a mixture of steam and water. The feed water from the economiser tubes enters the evaporator drum into which is also passed two-thirds of the superheated steam generated by the boiler. The superheated steam gives its superheat to the water in the drum and evaporates it to saturated steam.

Mixing Nozzles

The nozzles distribute and mix the superheated steam throughout the water in the evaporator drum.

Steam circulating pump

A steam circulating pump forces this saturated steam from the evaporator drum to the radiant superheater through the tube of the furnace wall.

Radiant superheater

The radiant superheater is placed in the furnace. The hot gases in the furnace are used for superheating the saturated steam from the drum. The radiant superheater receives heat from the burning fuel through radiation process.

Convection superheater

Steam from the radiant superheater enters the convection superheater where it is finally heated to the desired temperature of 500’C. The convection superheater receives heat from the flue gases entirely by convective heat transfer. Both radiant and convection superheater are arranged in series in the path of the flue gases.

Steam outlet

About one-third of the superheated steam from the convection superheater passes to the steam turbine while the remaining two-thirds is passed on to evaporator drum to evaporated the feed water to saturated steam.

Capacity

Capacity of the Loeffler boiler is about 100 Tonnes/Hr of superheated steam generated at a pressure of 140 kgf/sq.cm and at a temperature of 500’C.