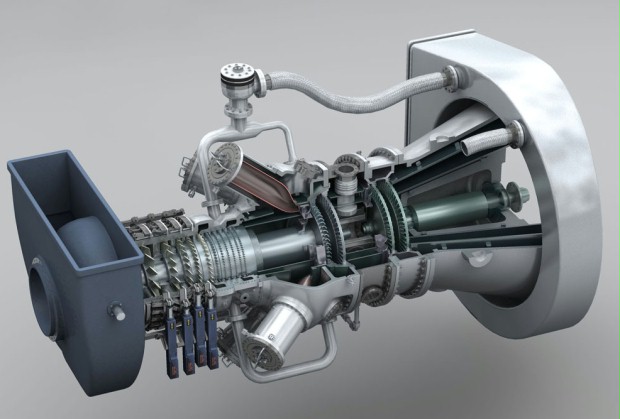

A gas turbine is also known as combustion turbine. It is a type of internal combustion engine. And it consists of an upstream rotating compressor coupled with the downstream turbine and a combustion chamber.

There are two types of gas turbines, which are used in the gas turbine power plant.

- High pressure turbine

- Low pressure turbine

High pressure turbine:

In the beginning the compressor shaft runs with the help of the starting motor. Through the high pressure turbine, burnt gases are expanded. To the turbine shaft, compressor shaft is coupled, as it drives the compressor shaft. Using the high pressure turbine, the starting motor and compressor is stopped. In the developed power 66% of the power is used to run the compressor and the remaining power that is 34% is used to generate electric power.

Low pressure turbine:

The main purpose of the low pressure turbine is to produce electric power. With the generator the low pressure turbine shaft is coupled. The burnt fuels are released from the high pressure turbine. The released burnt gases (enters the combustion chamber. Then from that it moves to the low pressure turbine. To the generator the turbine shaft is directly coupled. From there it produces the electricity. After separation, the exhaust hot gases from the low pressure turbine passes through the generator in advance to exhausted over the chimney into the air. The heat developed from the hot gases is recycled to preheat the air leaving the high pressure chamber before it enters the combustion chamber. The heat up of the air expands the efficiency of the combustion chamber.

Classification of gas turbine:

Gas turbines are divided in to two types .They are

· Open cycle gas turbine

· Closed cycle gas turbine

Open cycle gas turbine

In the open cycle gas turbine air is drawn in to the compressor from the atmosphere. The compressed air is heated by using the burner; the air must be burned directly. In the combustion chamber the fuel in the air inside maintains at constant pressure. From the combustion chamber the high pressure hot gases drive the turbine. The power must be developed when the turbine shaft rotates.

There is no self-starting in the Gas turbines. The starting motor drives the compressor till the fuel is injected in the combustion chamber. If the turbine frights gain speed then the starting motor is disconnected. The power established by the gas turbine is used to initiative the compressor and the remaining is used to initiative other machinery or generator.

In the open cycle gas turbine the system and the working fluid are replaced continuously and gases are drained into the atmosphere. Then the total flow derives from the atmosphere and again returns to the surrounding.

Closed cycle gas turbine

According to the closed cycle gas turbine, the compressed air from the surroundings is heated by using the heat exchanger (air heater). At constant pressure from the external source the heat is additionally given to the heat exchanger. High pressure working fluid increases over the turbine and then the power is developed. The exhaust working fluid must be cooled in a pre-cooler. Same fluid is sent into the compressor before the process is done. In the turbine same working fluid is always distributed. From an external source the fuel is required for adding heat so the fuel ranges from kerosene and then to the heavy oil. Straightly the fertilizer and coal slurry enter the turbine without reducing the efficiency.