Top Dead Centre (T.D.C):-

When the piston is at its top most position, i.e. the piston is closet to cylinder head, it is called top dead centre.

Bop Dead Centre (B.D.C):-

When the piston is at its lowest position, i.e. the piston is farthest from the cylinder head, it is called bottom dead centre.

Bore:-

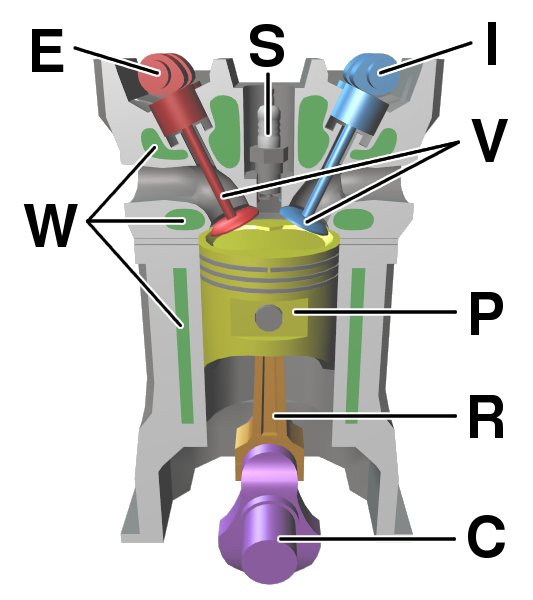

The inner diameter of the engine cylinder is known as bore. It can be measured precisely by a Vernier calliper or bore gauge. As the engine cylinder wears out with the passage of time, so the bore diameter changes to a larger value, hence the piston becomes lose in the cylinder, and power loss occurs. To correct this problem re-boring to the next standard size is done and a new piston is placed. Bore is denoted by the letter ‘D’. It is usually measured in mm (S.I. units) or inches (metric units). It is used to calculate the engine capacity (cylinder volume).

Stroke Length or Stroke:-

The distance travelled by the piston from its topmost positions (also called as Top dead centre TDC), to its bottom most position (or bottom dead centre BDC) is called stroke it will be two times the crank radius. It is denoted by letter h. Units mm or inches (S.L, Metric). Now we can calculate the swept volume as follows: (L = 2r)

VS = (πD²/4) x L

If D is in cm and L is also in cm than the units of V will be cm3 which is usually written as cubic centimeter or c.c.

Clearance Volume:-

The volume above the T.D.C is called as clearance volume, this is provided so as to accommodate engine valves etc. this is referred as (VC).

Swept Volume or Piston Displacement:-

The volume swept by piston while moving from T.D.C to B.D.C is called swept volume. This is referred as (VS).

Therefore, the total volume of the engine cylinder

V =VS + VC

Compression Ratio:-

It is the ratio of volume above the piston at B.D.C to the volume above the piston at T.D.C. It is the ratio of total volume of the cylinder (VS + VC), to the clearance volume (VC).

It is calculated as follows

rk = Total volume/Clearance volume

rk = (VS + VC)/VC

For petrol engine, it ranges from 8 to 12.

For diesel engine, it ranges from 15 to 24.

Power:-

It is the work-done in a given period of time. More power is required to do the same amount of work in a lesser time.

Indicated power (I.P):-

The power developed inside the engine cylinder is called the indicated power. It is expressed is kW. It is given by the area under engine indicator diagram.

Indicated power of an engine is given by, I.P = Pim L A N K/60,000

Indicator diagram:-

An indicated diagram is a graph between pressure and volume. The former being taken on vertical axis and the latter on the horizontal axis. This is obtained by an instrument known as indicator. The indicator diagrams are of two types;

(a) Theoretical or hypothetical

(b) Actual.

The theoretical or hypothetical indicator diagram is always longer in size as compared to the actual one. Since in the former losses are neglected.

The area of the indicator diagram represents the magnitude of the net work-done by the system in one engine cycle.

The area of the diagram = ad

The length of the diagram = ld

Therefore, the mean effective pressure (m.e.p) is defined as

Pm = (Area of Indicator diagram/Length of diagram) x constant

= (ad / ld) x k

Work-done in one engine cycle = Pm A L

For 2-stroke engine, work-done in one min. = Pm. A. L. N

For 4-stroke engine, work-done in one min. = Pm. A. L. N/2

Diagram Factor:-

The ratio of the area of the actual indicator diagram to the theoretical one is called diagram factor.

Brake Power (B.P):-

This is the actual power available at the crank shaft. The indicated power minus various power losses in the engine like, friction and pumping losses in the engine, gives brake power. It is measured by using Dynamometer and expressed in kW.

Brake power of an engine is given by, B.P = T. ω

Or, B.P = 2 π NT/60,000

Mean Effective Pressure (Pm or Pmef ):-

Mean effective pressure is that hypothetical constant pressure which is assumed to be acting on the piston during its expansion stroke producing the same work output as that from the actual cycle.

Or,

As piston performs power stroke, cylinder pressure decreases. Thus it is required to refer an average effective pressure throughout the whole power stroke. It is expressed in bars.

Mathematically,

Pm = Work Output/ Swept volume = Wnet /(V₁ – V₂)

It can also be shown as

Pm = (Area of Indicator diagram/Length of diagram) x constant

= (ad / ld) x k

The constant depends on the mechanism used to get the indicator diagram and has the unit, bar/m.

Indicated Mean Effective Pressure (Pim)

Indicated power of an engine is given by

I.P = Pim L A N K/60,000

Therefore, Pim = (60,000x I.P)/L A N K

Break Mean Effective Pressure (Pbm)

Similarly, the brake mean effective pressure is given by

Pbm = (60,000 x B.P)/L A N K

Engine Torque:-

It is the force of rotating action about the crank axis at any given instant of time.

It is given by, T = F. r

Where;

I.P = Indicated Power (kW)

B.P = Break Powder (kW)

Pim = Indicated mean effective pressure (N/m²)

Pbm = Break mean effective Pressure (N/m²)

L = Length of the stroke

A = (πD²/4) = Area of the piston (m²)

N = Number of power strokes

= rpm for 2-stroke engines = rpm/2 for 4-stroke

K = Number of cylinder.

T = Engine Torque (Nm)

F = Force applied to the crank (N)

r = Effective crank radius (m).

ω = Average velocity of crankshaft (rad/sec)

Mechanical Efficiency of Engine: ηmech = B.P/I.P

Otto cycle Efficiency: ηotto = 1- (1/rk ɤ – 1)

Diesel cycle Efficiency: [1 – (1/ɣ). (1/rk ɤ – 1)] x [(rcɤ – 1)/rc – 1)]

Where, rk = v₁/v₂ = Compression ratio

re = v₄/v₃ = Expansion ratio

rc = v₃/v₂ = Cut-off ratio

Also, rk = re x rc.