Materials play a crucial role in engineering, construction, and manufacturing. When subjected to external forces, materials experience stress and strain, which determine their strength, flexibility, and durability. Understanding these concepts is essential for designing safe and efficient structures, machinery, and products.

In this article, we’ll dive deep into stress and strain, their types, mathematical formulas, and real-world applications. 🔍

📌 What is Stress?

Stress (σ) is the internal force per unit area within a material when an external force is applied. It measures how much force a material can withstand before it fails.

🧮 Formula for Stress:

σ=FA\sigma = \frac{F}{A}

Where:

- σ (Stress) = Force per unit area (N/m² or Pascals, Pa)

- F = Applied force (Newtons, N)

- A = Cross-sectional area of the material (m²)

🔹 Types of Stress

-

Tensile Stress (Stretching) ➡️⬅️

- Occurs when a material is pulled apart (e.g., stretching a rubber band).

- Example: Steel cables in suspension bridges experience tensile stress.

-

Compressive Stress (Squashing) ⬅️➡️

- Happens when a material is pushed together (e.g., pressing a sponge).

- Example: Columns in buildings withstand compressive stress.

-

Shear Stress (Sliding) ↘️↖️

- When forces act parallel but in opposite directions, causing deformation.

- Example: Scissors cutting paper generate shear stress at the blade edges.

-

Torsional Stress (Twisting) 🔄

- When a material is subjected to twisting forces.

- Example: Drive shafts in vehicles experience torsional stress.

📌 What is Strain?

Strain (ε) is the deformation a material undergoes due to applied stress. It measures how much a material stretches or compresses relative to its original size.

🧮 Formula for Strain:

ε=ΔLL0\varepsilon = \frac{\Delta L}{L_0}

Where:

- ε (Strain) = Change in length per unit of original length (unitless)

- ΔL = Change in length (m)

- L₀ = Original length of the material (m)

🔹 Types of Strain

-

Tensile Strain (Stretching) 🔼

- Occurs when a material elongates due to tensile stress.

-

Compressive Strain (Shortening) 🔽

- Happens when a material shortens due to compressive stress.

-

Shear Strain (Angular Deformation) 🔀

- When a material changes shape due to shear stress.

📏 Hooke’s Law: The Stress-Strain Relationship

For many materials, stress and strain are proportional within the elastic limit. This relationship is defined by Hooke’s Law:

σ=E⋅ε\sigma = E \cdot \varepsilon

Where:

- E = Young’s Modulus (Modulus of Elasticity)

- σ = Stress

- ε = Strain

Young’s Modulus (E) indicates a material’s stiffness. A higher E means the material is more resistant to deformation.

| Material | Young’s Modulus (GPa) |

|---|---|

| Steel | 200 |

| Aluminum | 70 |

| Rubber | 0.01 |

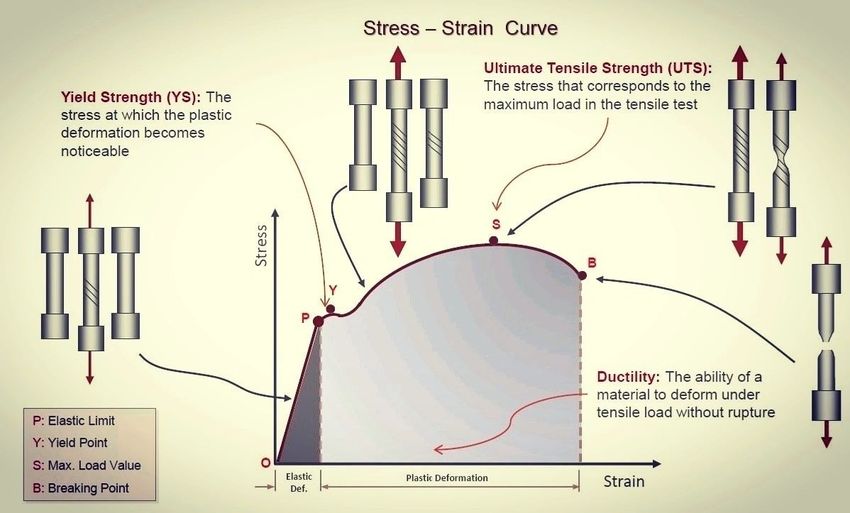

🔥 Stress-Strain Curve: How Materials Behave Under Load

The stress-strain curve helps visualize how materials react to different levels of stress.

📊 Stages in a Stress-Strain Curve

-

Elastic Region (Material returns to its original shape)

- Follows Hooke’s Law.

- Example: A stretched rubber band returns to normal.

-

Yield Point (Permanent deformation starts)

- The material begins to deform permanently.

- Example: A bent paper clip doesn’t return to its original shape.

-

Plastic Region (Deformation continues without breaking)

- The material elongates further but hasn’t broken yet.

-

Ultimate Strength (Maximum stress the material can handle)

- The highest point on the curve.

-

Fracture Point (Material breaks)

- Beyond this, the material fails completely.

🏗️ Real-World Applications of Stress and Strain

-

Bridges & Buildings 🏛️

- Engineers calculate stresses in beams and columns to prevent collapse.

-

Aircraft & Automobiles ✈️🚗

- Materials must withstand high stresses while remaining lightweight.

-

Sports Equipment 🏀🏋️♂️

- Rackets, helmets, and bicycles are designed to endure stress while being flexible.

-

Biomedical Applications 🦾

- Prosthetic limbs and bones must mimic real bone strength and strain properties.

⚖️ Factors Affecting Stress and Strain

🔹 Material Type – Some materials handle stress better than others.

🔹 Temperature – High temperatures can weaken materials.

🔹 Loading Rate – Sudden forces (like impacts) can cause unexpected failures.

🔹 Shape & Size – Thicker materials resist stress better.

🎯 Conclusion

Understanding stress and strain is vital in engineering, physics, and materials science. By studying how materials respond to forces, we can design stronger, safer, and more efficient structures and products. Whether you’re building skyscrapers or designing airplanes, mastering these principles ensures optimal performance and longevity.