Gears and gearboxes are essential components in mechanical systems, allowing machines to transmit power efficiently, control speed, and multiply torque. From cars and industrial machines to wind turbines and robots, gears play a vital role in power transmission and motion control.

In this article, we’ll explore how gears and gearboxes work, different types of gears, and their industrial applications. 🚀

1. What Are Gears and Gearboxes? 🤔⚙️

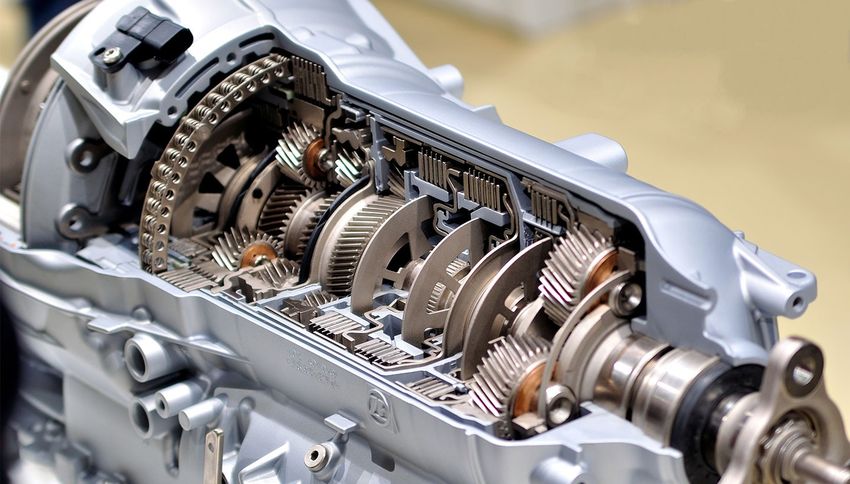

A gear is a mechanical component with teeth that meshes with another gear to transmit torque (rotational force). A gearbox (or gear train) is an enclosed system of gears that adjusts speed, torque, and direction of motion.

📌 Key Functions of Gears & Gearboxes:

✅ Increase or decrease speed (e.g., bicycles, cars).

✅ Multiply torque (e.g., heavy machinery, wind turbines).

✅ Change direction of motion (e.g., right-angle gearboxes).

✅ Ensure smooth power transmission (e.g., industrial conveyor systems).

📍 Example: In a car, the gearbox allows the engine to run efficiently at different speeds, enabling smooth acceleration and fuel efficiency.

2. How Gears Work: The Science Behind It 🔬⚙️

Gears function based on the principles of torque and rotational speed.

🔹 Gear Ratio & Speed Control 🚗

The gear ratio determines how power is transmitted:

Gear Ratio=Driven Gear TeethDriving Gear Teeth\text{Gear Ratio} = \frac{\text{Driven Gear Teeth}}{\text{Driving Gear Teeth}}

- If the driving gear is smaller than the driven gear → Speed decreases, but torque increases.

- If the driving gear is larger than the driven gear → Speed increases, but torque decreases.

📍 Example: In bicycles, shifting gears allows cyclists to increase torque for climbing hills or increase speed on flat roads.

🔹 Torque Multiplication & Load Handling 🏋️

- A high gear ratio increases torque, useful for heavy-duty applications.

- Example: Cranes and excavators use high torque gearboxes to lift heavy loads.

3. Types of Gears & Their Applications 🏭⚙️

Different gears serve different purposes in machines, vehicles, and industrial equipment.

🔹 1. Spur Gears ⚙️

✅ Straight teeth, simple design.

✅ Efficient for low-speed applications.

✅ Used in clocks, conveyor belts, and simple gear trains.

📍 Example: Mechanical clocks use spur gears to regulate time.

🔹 2. Helical Gears ⚙️🌀

✅ Teeth are angled, reducing noise and wear.

✅ Handle higher speeds & loads compared to spur gears.

✅ Used in automobile transmissions, industrial mixers, and power tools.

📍 Example: Car gearboxes use helical gears for smoother and quieter operation.

🔹 3. Bevel Gears 🔄

✅ Conical shape, transmits power at right angles.

✅ Used in differentials, hand drills, and marine drives.

📍 Example: Car differentials use bevel gears to allow wheels to rotate at different speeds while turning.

🔹 4. Worm Gears 🐍⚙️

✅ Worm (screw-like gear) engages a toothed wheel.

✅ Provides high torque, low-speed reduction.

✅ Used in lifts, conveyors, and heavy-duty machines.

📍 Example: Elevator systems use worm gears for controlled movement.

🔹 5. Planetary Gears 🪐

✅ Multiple gears rotate around a central gear.

✅ Used for compact, high-torque transmissions.

✅ Found in automatic car transmissions, wind turbines, and robotics.

📍 Example: Electric vehicles (EVs) use planetary gears for efficient torque control.

4. How Gearboxes Work: Power Transmission in Machines 🚀

A gearbox is a system of gears that adjusts speed, torque, and power flow in mechanical devices.

🔹 Types of Gearboxes & Their Uses

| Gearbox Type | Function | Applications |

|---|---|---|

| Manual Transmission 🚗 | Driver shifts gears manually | Cars, trucks, motorcycles |

| Automatic Transmission 🚘 | Changes gears automatically | Modern vehicles, hybrid cars |

| Industrial Gearboxes 🏭 | Transmit high torque | Factories, conveyors, power plants |

| Planetary Gearbox 🛠️ | Compact, high torque output | Wind turbines, robotic arms |

📍 Example: Wind turbines use planetary gearboxes to convert slow rotor speeds into high-speed generator motion.

5. Industrial Applications of Gears & Gearboxes 🏗️⚙️

🚗 1. Automotive Industry

- Gearboxes regulate engine speed for different driving conditions.

- Differentials allow smooth turning on roads.

📍 Example: Tesla’s electric cars use single-speed gearboxes instead of traditional multi-gear transmissions.

🏭 2. Manufacturing & Industrial Machinery

- Gear trains power conveyor belts and mixers.

- High-torque gearboxes operate heavy-duty machines.

📍 Example: Factories use worm gear reducers to control speed in conveyor systems.

🌍 3. Wind Energy & Power Generation

- Gearboxes increase turbine speed to generate electricity efficiently.

📍 Example: Siemens wind turbines use planetary gear systems for smooth energy conversion.

🦾 4. Robotics & Automation

- Gears control robotic arms and servo motors.

- Precision planetary gearboxes enable smooth movement.

📍 Example: Industrial robots use harmonic gears for precise motion control.

✈️ 5. Aerospace & Defense

- Helicopter gear systems adjust rotor speeds.

- Jet engines use precision gears for thrust control.

📍 Example: NASA spacecraft use specialized gearboxes for space exploration.

6. Common Gearbox Problems & Maintenance Tips 🔧⚠️

| Issue | Cause | Solution |

|---|---|---|

| Gear Wear 🏭 | Friction & lack of lubrication | Use high-quality lubricants |

| Excessive Noise 🔊 | Misalignment or damaged teeth | Realign gears, replace worn parts |

| Overheating 🔥 | Poor ventilation, high load | Use cooling systems, check lubrication |

| Vibration & Jamming 🛠️ | Loose bearings or broken teeth | Inspect & replace faulty components |

📍 Example: Regular oil changes in car gearboxes prevent overheating and wear.

7. Future of Gears & Gearboxes: What’s Next? 🔮🚀

With advances in materials, AI, and smart automation, gear technology is evolving rapidly.

🔹 Smart Gearboxes – AI-powered gear monitoring for predictive maintenance.

🔹 Lightweight Composite Gears – Reducing weight for fuel efficiency.

🔹 Magnetic Gears – Frictionless power transmission for higher efficiency.

🔹 3D-Printed Gears – Faster prototyping and complex designs.

📍 Example: NASA is developing magnetic gears for future spacecraft propulsion.

8. Conclusion 🏆⚙️

Gears and gearboxes transfer power efficiently in vehicles, machinery, wind turbines, and robotics. Understanding gear types, gear ratios, and maintenance is essential for engineers working in automotive, aerospace, manufacturing, and renewable energy industries.

🚀 Want to explore more? Try observing how gears work in bicycles, clocks, or cars!