Casting is one of the oldest and most essential manufacturing processes, used to create complex metal, plastic, and ceramic parts in industries such as automotive, aerospace, and construction. By pouring liquid material into a mold, engineers can produce high-strength, intricate components efficiently.

In this article, we’ll explore how casting works, different casting methods, and its industrial applications.

1. What is Casting? 🤔🏗️

Casting is a manufacturing process where a molten material (metal, plastic, or ceramic) is poured into a mold, allowed to cool, and solidifies into the desired shape.

📌 Key Advantages of Casting:

✅ Produces complex shapes that would be difficult with machining.

✅ Suitable for mass production of identical parts.

✅ Works with a wide range of materials (metals, polymers, ceramics).

✅ Cost-effective for large-scale manufacturing.

📍 Example: Engine blocks, turbine blades, and jewelry are commonly made using casting.

2. The Casting Process: Step-by-Step 🔄🔥

The casting process consists of several key steps:

🔹 Step 1: Pattern Making & Mold Preparation

- A pattern (replica of the final part) is created using wood, plastic, or metal.

- The mold cavity is formed around the pattern.

🔹 Step 2: Melting & Pouring

- The raw material (metal, plastic, or ceramic) is heated to a molten state.

- The molten material is poured into the mold.

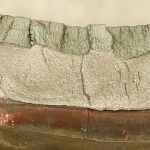

🔹 Step 3: Cooling & Solidification

- The material cools and takes the shape of the mold.

- Cooling rate affects grain structure and strength.

🔹 Step 4: Removing the Casting

- The solidified part is removed from the mold by breaking or opening it.

🔹 Step 5: Finishing & Quality Control

- Excess material is trimmed, polished, and machined if needed.

- Non-destructive testing (NDT) ensures quality.

📍 Example: In automobile manufacturing, aluminum engine blocks are cast, machined, and tested for defects before assembly.

3. Types of Casting Processes 🏗️🔄

Casting methods vary based on the material, shape complexity, and required precision.

🔹 1. Sand Casting ⏳🏺

✅ Most common casting method using sand molds.

✅ Suitable for large, heavy, and complex parts.

✅ Low cost but lower surface finish quality.

📍 Example: Engine blocks, pump housings, and industrial machinery parts.

🔹 2. Investment Casting (Lost Wax) 🕯️🔬

✅ Uses a wax pattern, which melts away before casting.

✅ Produces high-precision parts with smooth finishes.

✅ Ideal for small, intricate components.

📍 Example: Aerospace turbine blades, jewelry, and medical implants.

🔹 3. Die Casting 🏭🔩

✅ Molten metal is forced into a steel mold at high pressure.

✅ Produces accurate, smooth parts with thin walls.

✅ Ideal for mass production of lightweight metal components.

📍 Example: Automobile engine parts, aluminum alloy wheels, and electrical enclosures.

🔹 4. Centrifugal Casting 🌀🔥

✅ Uses rotational force to distribute molten material evenly.

✅ Produces hollow, cylindrical parts with high strength.

✅ Common in pipe, bearing, and roller manufacturing.

📍 Example: Industrial pipes, gears, and bushings.

🔹 5. Continuous Casting 🔄♨️

✅ Produces long metal sheets, rods, or bars continuously.

✅ Used in mass production of structural metals.

✅ Improves material properties and reduces waste.

📍 Example: Steel sheets, copper rods, and aluminum billets for construction.

4. Industrial Applications of Casting 🏭🚗

Casting is used across multiple industries due to its ability to create complex, durable parts efficiently.

🚗 1. Automotive Industry

- Engine blocks, cylinder heads, brake discs (sand & die casting).

- Lightweight aluminum wheels (die casting).

📍 Example: Tesla uses aluminum die casting for its car chassis to reduce weight and improve efficiency.

✈️ 2. Aerospace Industry

- Turbine blades & aircraft components (investment casting).

- High-strength, lightweight structures (titanium & nickel alloy casting).

📍 Example: Boeing & Airbus use investment casting for jet engine turbine blades.

🏗️ 3. Construction & Infrastructure

- Steel beams, pipes, and fittings (continuous & centrifugal casting).

- Bridge components and rail tracks.

📍 Example: Steel I-beams for skyscrapers are made using continuous casting.

🛢️ 4. Oil & Gas Industry

- Pipeline valves, pumps, and pressure vessels (sand casting).

- Corrosion-resistant alloy components for offshore drilling.

📍 Example: Oil refinery heat exchangers are made with specialized casting methods.

🔬 5. Medical & Biomedical Industry

- Prosthetic implants and surgical tools (investment casting).

- Titanium bone replacements and dental implants.

📍 Example: Artificial hip joints are created using precision investment casting.

5. Challenges & Solutions in Casting 🚀🔍

| Challenge | Cause | Solution |

|---|---|---|

| Porosity (tiny air bubbles) | Gas trapped during solidification | Vacuum-assisted casting, degassing techniques |

| Shrinkage defects | Uneven cooling and contraction | Proper mold design, risers to compensate for shrinkage |

| Cracking & Warping | High thermal stresses | Controlled cooling rates, alloy selection |

| Surface Roughness | Sand grain size, improper mold coating | Using finer sand, better mold coatings |

📍 Example: In aerospace casting, engineers use high-vacuum casting to prevent defects in turbine blades.

6. The Future of Casting Technology 🔮🏗️

With advancements in materials and automation, casting is evolving into a more efficient and precise process.

🔹 Smart Casting & AI Integration 🤖

✅ AI-powered real-time defect detection reduces waste.

✅ IoT sensors monitor casting temperature and flow dynamics.

📍 Example: GE Aviation uses AI-assisted casting for aircraft engine components.

🔹 3D Printing & Hybrid Casting 🖨️🔥

✅ 3D-printed molds allow for faster, more complex designs.

✅ Hybrid manufacturing combines casting with additive manufacturing.

📍 Example: 3D-printed sand molds are revolutionizing traditional sand casting.

🔹 Eco-Friendly Casting Solutions 🌱

✅ Recyclable materials reduce waste.

✅ Low-energy, sustainable alloys improve efficiency.

📍 Example: Tesla’s Gigacasting uses recycled aluminum alloys for car frames.

7. Conclusion 🏆🔩

Casting remains a fundamental process in modern manufacturing, enabling complex, durable, and cost-effective production across industries. With advancements in automation, AI, and 3D printing, casting is becoming more efficient and sustainable.

🚀 Want to explore more? Try visiting a local foundry or experimenting with DIY metal casting!