Computer-Aided Design (CAD) software is a game-changer in mechanical engineering, enabling precise design, analysis, and simulation of mechanical components. Mastering CAD software can provide a competitive edge in mechanical design, improving productivity, efficiency, and innovation. This article explores key strategies to become proficient in CAD and stay ahead in the industry.

1. Understanding the Importance of CAD in Mechanical Design

CAD software plays a crucial role in:

- Product Development: From conceptualization to prototyping, CAD simplifies the design process.

- Precision and Accuracy: Ensures exact measurements and tolerances in designs.

- Simulation and Analysis: Allows stress analysis, thermal analysis, and motion simulation before manufacturing.

- Collaboration: Enables easy sharing of designs across teams and departments.

Popular CAD software includes AutoCAD, SolidWorks, CATIA, Siemens NX, Fusion 360, and Creo.

2. Choosing the Right CAD Software

Different CAD software cater to different needs:

- AutoCAD – Best for 2D drafting and basic 3D modeling.

- SolidWorks – Ideal for parametric design and simulation.

- CATIA – Used in aerospace and automotive industries for complex 3D modeling.

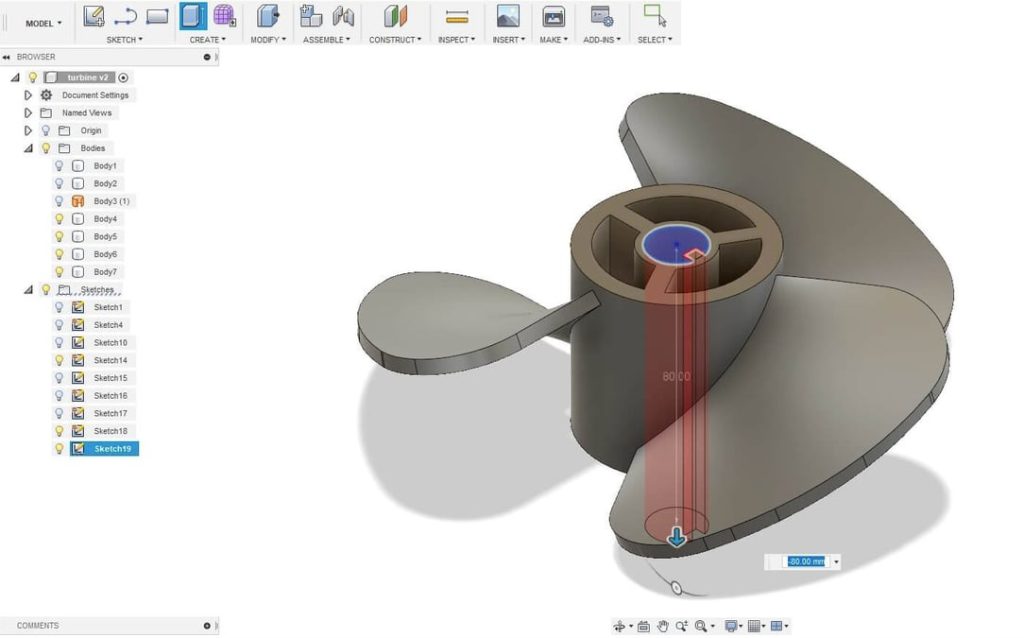

- Fusion 360 – Cloud-based CAD with integrated CAM and CAE tools.

- Siemens NX – Advanced software for product engineering and manufacturing.

- PTC Creo – Excellent for parametric modeling and real-time simulation.

Choosing the right software depends on industry requirements and personal career goals.

3. Mastering the Basics of CAD Software

To build a strong foundation, focus on:

- Understanding the Interface – Learn toolbars, shortcuts, and workspace customization.

- Sketching & Constraints – Master 2D sketches and apply constraints for precise geometry.

- 3D Modeling Techniques – Practice extrusion, lofting, and revolved features.

- Assemblies & Joints – Learn how to combine multiple parts into an assembly.

- Engineering Drawings – Create detailed technical drawings with annotations and dimensions.

4. Advanced CAD Skills to Gain a Competitive Edge

A. Parametric Modeling

- Use constraints and relations to make flexible, editable designs.

- Example: Designing a gearbox where modifying one gear’s size automatically adjusts others.

B. Finite Element Analysis (FEA)

- Learn stress, strain, and thermal analysis within CAD software.

- Example: Analyzing load distribution in a bridge component before manufacturing.

C. Computer-Aided Manufacturing (CAM) Integration

- Understand how CAD integrates with CNC machining for manufacturing.

- Example: Using Fusion 360 to generate G-code for CNC milling.

D. Generative Design & AI-Assisted Modeling

- Leverage AI tools to optimize designs for weight reduction and efficiency.

- Example: Generative design creating lightweight aerospace components.

5. Hands-On Practice and Real-World Projects

Practical Exercises:

- Design a simple mechanical part (e.g., a bracket or a shaft).

- Create a gearbox assembly with motion constraints.

- Perform a stress analysis on a beam structure.

Open-Source CAD Projects:

- Contribute to online repositories like GrabCAD and Thingiverse.

- Reverse-engineer everyday objects and redesign them for improvement.

6. Leveraging Online Courses and Certifications

Enhance skills with structured learning:

- Coursera & Udemy – Courses on AutoCAD, SolidWorks, and Fusion 360.

- Dassault Systèmes Certifications – SolidWorks and CATIA certification.

- Autodesk Certification – AutoCAD and Fusion 360 certification.

- PTC Creo & Siemens NX Training – Available through official platforms.

These certifications boost credibility and career opportunities.

7. Staying Updated with CAD Trends

A. Cloud-Based CAD Solutions

- Tools like Fusion 360 and Onshape enable remote collaboration.

- Cloud storage ensures easy access to designs from anywhere.

B. Virtual Reality (VR) & Augmented Reality (AR) in CAD

- VR allows immersive design visualization.

- AR helps in real-time assembly guidance and prototyping.

C. AI and Automation in CAD

- AI-driven design tools enhance creativity and reduce modeling time.

- Example: AI suggesting optimal material choices based on simulation results.

8. Career Benefits of CAD Mastery

Proficiency in CAD opens doors to:

- Mechanical Design Engineer – Working on product and machinery design.

- Automotive/Aerospace Engineer – Designing aircraft and vehicle components.

- Industrial Designer – Creating ergonomic and functional product designs.

- Manufacturing Engineer – Implementing CAD-CAM integration for production.

Companies prioritize CAD experts with hands-on experience, making mastery a valuable skill.

Conclusion

Mastering CAD software is essential for success in mechanical design. By choosing the right software, practicing regularly, obtaining certifications, and staying updated with industry trends, engineers can gain a competitive edge in their careers. The key to CAD expertise is continuous learning, hands-on experience, and adapting to new technologies in mechanical design.